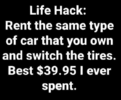

**RANT** -- just go watch nightline if you cant handle it--**

true

@Robert Herndon but sad -- when the issues of the LOW end (800.00 and up) gibsons are not seen (or seldom seen) in the 400-500.00 epiphones or the 250-300.00 Squires.......

CNC machines and quality control should be AT LEAST as good across a brands range -- wouldnt you agree ??-- we arent COBBLING these things from fallen logs with rude tools and fire

its ALL computerized and CNC driven ....... the "care" comes after the build and in the little extras-- and low end gibbos are hit and miss while low end

well EVERY OTHER MAKER are rather good

case in point -- bought one of these brand new for roughly 250.00 ---

View attachment 83403

it is perfectly fine -- excellent build quality in fact great finish and fit-- good tones --great pups -- great frets... great build-- holds tune intonates plays works ..... surely if THOMAN can do that... for 250.00 ...............Gibson SHOULD be able to for ?? 500.00 -- 800.00 ... I mean come on ...

Dont believe me ? PM

@Hackmaster ...he has fondled this HB ... and he OWNS a REAL BESPOKE PRS.... he was FLOORED by the quality for $

That ISNT harley BEnton/THomans fault ...... the fact these arguments and comparisons happen ISNT because the cheap stuff is SOOO GOOD .... its flat out simply because

and I quote "people are getting tired of getting screwed by buying a "brand" that claims quality and doesnt DELIVER."

ive said it a MILLION times

IF GIBSON WANTS TO BE THE PREMIER BEST AWESOME "THE poop" BOSS KILLER AMERICAN BRAND ........................then they should .... DELIVER it ... not just

MARKET it .

they claim "big dog on campus" status with their prices ... but in many cases they arent at all... they are overpriced and half assed -- they WERE "the poop" -- but you can only milk the 50s/60's so long and I think Rhett and his video are showing that the youth (and future guitarists) of this era ....arent falling for "playing authentic" they are playing WHAT WORKS AND SOUNDS GOOD .... NOW ... not when LEs Paul was on broadcast TV .....that people received with RABBIT EARS for free while drinking Ovaltine ..... and saying AW SHUCKS PAW .......

and Im bored..... argue amongst yourselves...... but deep down even the ones who will post how WONDERFUL ALL GIBSON ARE AND THEY ARE INFALABLE -- (as they show pics of vintage ones... or custom copies they had or have built) -know Im right -- a new gibson is about a 60/40 gamble when you buy period

if your not KNOWLEDGEABLE or KNOW a good gutiar when you play it -- you MIGHT GET SCREWED .... thats the reality

Your ods of getting a GOOD playable guitar for the same $ (or less) are better with Fender Squire Charvel Schecter Harley BEnton Yamaha -- Godin -- etc etc etc at worst those are a 40/60 gamble and from what Ive seen more like 20/80 bad to good .....

so ... yep there ya go Friday Rant .....

CNC imparts a very consistent level of quality to a given product. In this case, a guitar.

If you look at Schecter - made by World Musical Instruments of Korea - the consistency and build quality are just phenomenal.

Zakk contracted with WMI/Schecter to build his Wylde Audio guitars for this reason.

The greater the amount of hand fitting and assembly, the greater the chance for human error.

I agree with you that the "youth (and future guitarists) of this era" are very content with Fender or _______ and that's partially price, but also an progressively targeted marketing campaign.

But, this modern era is also no longer producing true "guitarists," but rather enthusiasts who grew up idolizing Nirvana, Green Day and Blink-182.

I believe that also has a lot to do with the state of things.

The Kurt Cobain Jag-Stang is a terrible instrument on so many levels - funky trems that wont stay in tune, anemic pickups, oddball controls - but it's a top seller because Cobain is still idolized.

I believe that there has been a huge change in Gibson's quality in recent years and I'm hoping that trend continues because the Gibson line has great potential.

For me, I really like the way a Les Paul feels and sounds. I prefer the shorter scale and reduced string tension. It's easier for me to bend strings and sling vibrato on a Gibson for these reasons.

My YelloStrat is a simple, rugged guitar. That's what I like about Leo's design. My Strat will lay in my trunk all day while im at work and go to rehearsal or a performance after work and its still in tune.

The Stratocaster is by far easier easier/faster to setup and it's very forgiving in terms of being knocked around or dropped.

But it sucks from almost every other standpoint.

It's much harder or me to play it. Let's say that I notice that I'm working harder playing the Stratocaster.

If I play 3-4 hours with a Les Paul, I don't feel worn out, but despite the Stratocaster weighing half as much as the Les Paul (my 2021 Gibson is 10.6 pounds) my hands and forearms are feeling a difference when I'm playing the Stratocaster.

The wider fret spacing and the increased string tension - from the longer scale length - make it a lot harder (for me) to impart the same level of intensity to my playing that just seems to flow out of me on a shorter scale guitar.

When I've put lighter strings on the Stratocaster, I break them in the middle of a show, so I'm sticking with .010's now and I'm getting zero breaks during a performance.

The Stratocaster - to me - is like the old boots that you don't care if they get scuffed up. It's a useful tool.

One of the reasons I decided to build this recent SG is that I know I can build a better SG than I can buy and with features I couldn't even get from Gibson's custom shop.

Second reason is to get Les Paul humbucker punch in a lighter weight package with a more 'user friendly' scale length.

True, there are some decent imported guitars out there and nobody should feel like they can't or shouldn't buy what they want, but I like my USA Gibson and I prefer a USA or UK made product over the import offerings in general, IMHO anyway.

I'm using UK made Celestion speakers too and there's just no comparison to their imported Celestions.

My Gibson is my only commercially made guitar. Everything else I have is custom and my pickiness is a huge part of that.