SG Lou

Well-Known Member

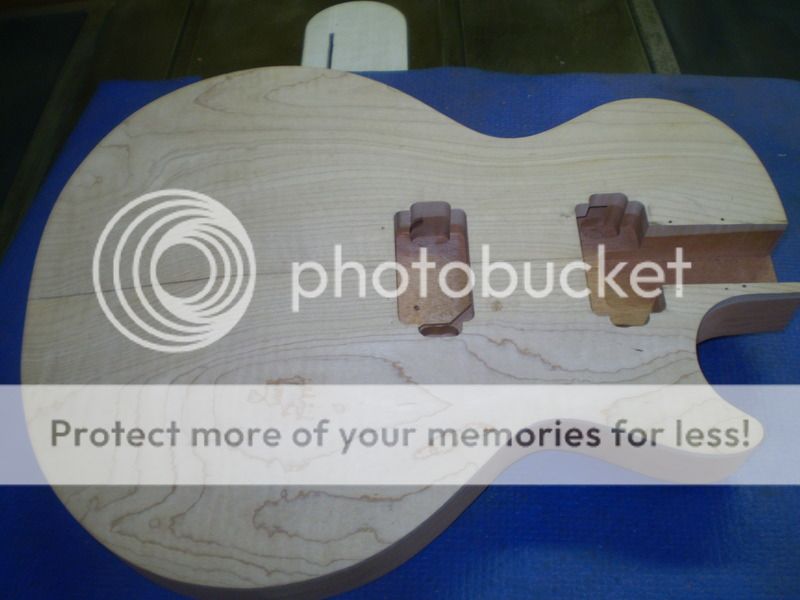

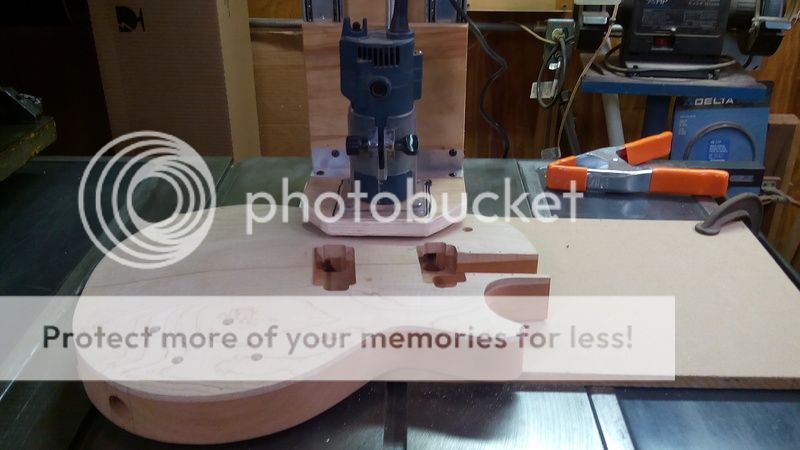

Well I did state this is a "59" replica build but I must elaborate, I'm using 59 specs and measurements but that's about it . That idea got totally blown out the window when the customer came over, picked up the rough cut body and cried....."It's too heavy" so had no choice but to weight relieve it.

You'll see in the pictures.

So, being it's NOT going to be a true 59 replica a few items were changed.

Mahogany Body and Neck, Indian Rosewood FB ( keeping my stash of Braz RW for myself...hehehe).

Celluloid Nitrate neck and body binding along with the inlays, 2 way truss rod instead of the traditional compression rod, American Holly headstock overlay.

Anyway:

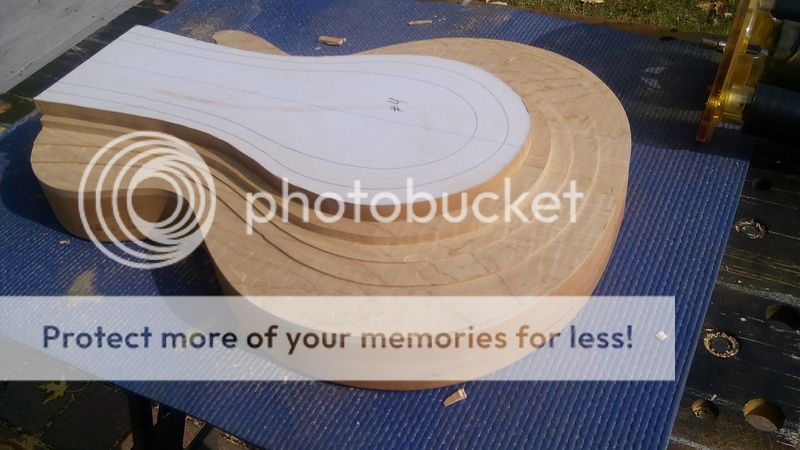

weight relief holes actually dropped the completed body down from 6.8 lbs to 4.8 lbs after all of the carving was done.

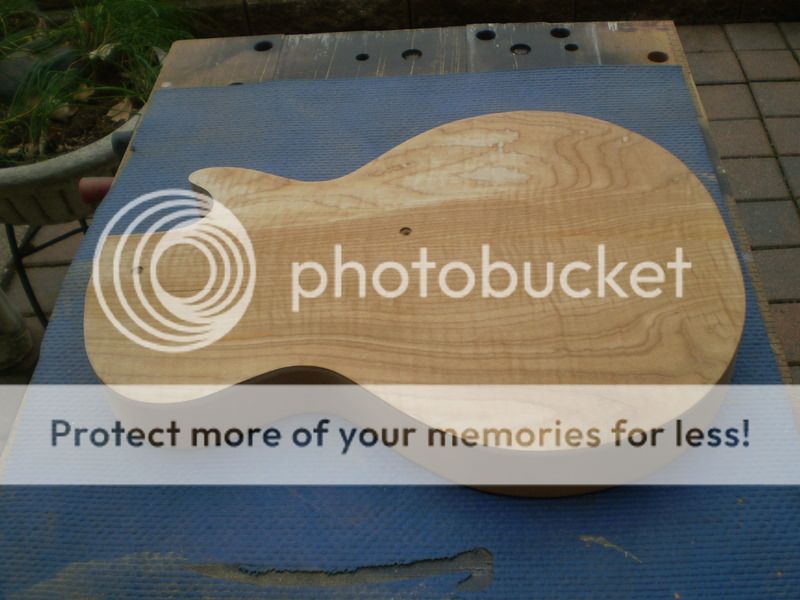

Book matched Eastern Flamed Maple.....I got a HUGE surprise after it was done being carvied. You'll see further on.

You'll see in the pictures.

So, being it's NOT going to be a true 59 replica a few items were changed.

Mahogany Body and Neck, Indian Rosewood FB ( keeping my stash of Braz RW for myself...hehehe).

Celluloid Nitrate neck and body binding along with the inlays, 2 way truss rod instead of the traditional compression rod, American Holly headstock overlay.

Anyway:

weight relief holes actually dropped the completed body down from 6.8 lbs to 4.8 lbs after all of the carving was done.

Book matched Eastern Flamed Maple.....I got a HUGE surprise after it was done being carvied. You'll see further on.