You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

When Stratocaster Nuts Drive You Nuts - Keeping The 6-Screw Fender Tremolo In Tune:

- Thread starter Inspector #20

- Start date

Ok...

I'm noticing this super frequently....lateral misalignment on Stratocaster nut slots. Every one I have set up lately (7 guitars today alone) all have laterally string binding. The usual practice is just make the slots bigger, but in actuality, re-making the nut is the correct fix.

The WORST was the factory installed Graph Tech Tusq XL. The 1-3/4" Warmoth neck comes with a pre-slotted nut and it was off by a mile...

Bone nut was only marginally better...

Also visible in this shot....

So, today, I shifted the strings to try and get them as straight through the nut as I could...

I'm noticing this super frequently....lateral misalignment on Stratocaster nut slots. Every one I have set up lately (7 guitars today alone) all have laterally string binding. The usual practice is just make the slots bigger, but in actuality, re-making the nut is the correct fix.

The WORST was the factory installed Graph Tech Tusq XL. The 1-3/4" Warmoth neck comes with a pre-slotted nut and it was off by a mile...

Bone nut was only marginally better...

Also visible in this shot....

So, today, I shifted the strings to try and get them as straight through the nut as I could...

Arg, made me realize these are going to be off by at least half the post diameterOk...

I'm noticing this super frequently....lateral misalignment on Stratocaster nut slots. Every one I have set up lately (7 guitars today alone) all have laterally string binding. The usual practice is just make the slots bigger, but in actuality, re-making the nut is the correct fix.

The WORST was the factory installed Graph Tech Tusq XL. The 1-3/4" Warmoth neck comes with a pre-slotted nut and it was off by a mile...

View attachment 69153

Bone nut was only marginally better...

View attachment 69151

Also visible in this shot....

View attachment 69152

So, today, I shifted the strings to try and get them as straight through the nut as I could...

View attachment 69155

Arg, made me realize these are going to be off by at least half the post diameter

View attachment 69160

That would be problematic with a tremolo, but maybe not as serious with a hardtail.

It’s gonna have a trem.That would be problematic with a tremolo, but maybe not as serious with a hardtail.

It’s gonna have a trem.

You might need to try and break the strings at the nut like a Gibson...

Thanks Robert, I’d love to have ya here to help. No hurry though, there’s still a lot on my plate and this build is fill in work. The drywall guy finished today, which means I have painting to do and then get a flooring contractor. Also just got a quote from the architect firm for doing the plans for our rear deck. This is going to be a year long effort from design, permits, winter off, then find a construction firm.@Don O - I will come help with the nut when you ae ready...

Ok...so, if we follow the recommendations of most luthier's, we want 1/3 of the string out of the nut...like this:

So, I tried it...

When I back-pick my open 'E,' I knock the 'b' and 'e' out of their slots and leave them hanging alongside the neck.

So, I had to seat the strings progressively deeper in the nut until they stopped popping out...

So, I tried it...

When I back-pick my open 'E,' I knock the 'b' and 'e' out of their slots and leave them hanging alongside the neck.

So, I had to seat the strings progressively deeper in the nut until they stopped popping out...

Last edited:

Thanks Robert, I’d love to have ya here to help. No hurry though, there’s still a lot on my plate and this build is fill in work. The drywall guy finished today, which means I have painting to do and then get a flooring contractor. Also just got a quote from the architect firm for doing the plans for our rear deck. This is going to be a year long effort from design, permits, winter off, then find a construction firm.

I have an idea for the nut already...

Buy a few Graph Tech Tusq XL blanks...

Graph Tech Black Tusq XL PT-2200-00

Last edited:

I have some on order. Got some white ones too.I have an idea for the nut already...

Buy a few Graph Tech Tusq XL blanks...

Graph Tech Black Tusq XL PT-2200-00

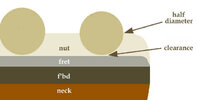

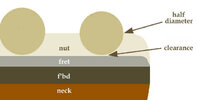

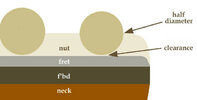

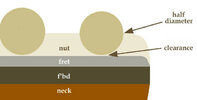

How correct nut profile should look from the side:

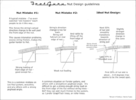

Correct nut slot profile as viewed from the top:

Nut profile detail. You want .004" larger slot than the string at the point of contact and the string should not contact the floor more than 2/3rds the distance of the nut.

On wound strings, 1/2 of the string should be in the nut and on plain strings, they should be level with the top of the nut.

In some cases, where a player will tend to "back pick" the strings aggressively, it's advantageous to run the strings deeper in the nut. In these cases, i suggest approximately the diameter of the string below the top surface of the nut. See images above.

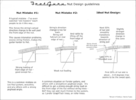

Good diagram on nut slotting demonstrating correct floor profile and fall-away.

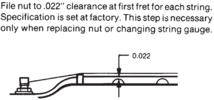

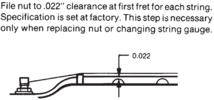

1st fret to string clearance should be no less than .022" and no greater than .030" respectively.

Be sure to set relief before adjusting 1st fret action height.

Correct nut slot profile as viewed from the top:

Nut profile detail. You want .004" larger slot than the string at the point of contact and the string should not contact the floor more than 2/3rds the distance of the nut.

On wound strings, 1/2 of the string should be in the nut and on plain strings, they should be level with the top of the nut.

In some cases, where a player will tend to "back pick" the strings aggressively, it's advantageous to run the strings deeper in the nut. In these cases, i suggest approximately the diameter of the string below the top surface of the nut. See images above.

Good diagram on nut slotting demonstrating correct floor profile and fall-away.

1st fret to string clearance should be no less than .022" and no greater than .030" respectively.

Be sure to set relief before adjusting 1st fret action height.

Last edited:

String trees are not necessary with vintage style, hollow post tuners, or with long-post modern tuners. When strings are wound to the correct specifications, they will naturally provide sufficient downforce in the nut, as shown here:

With vintage-style, hollow post tuners as shown, cut strings to the following specifications:

E = 30-3/4"

A= 31-1/2"

D = 32-1/2"

G = 34-3/4"

B = 35-1/2"

e = 36-1/2"

If string trees are used, only a true roller type should be used, such as these nade by Bitterroot Guitars:

String trees should be shimmed for .075" to .100" string deflection.

More deflection will not keep the string seated, will not increase sustain and WILL cause tuning stability problems.

With vintage-style, hollow post tuners as shown, cut strings to the following specifications:

E = 30-3/4"

A= 31-1/2"

D = 32-1/2"

G = 34-3/4"

B = 35-1/2"

e = 36-1/2"

If string trees are used, only a true roller type should be used, such as these nade by Bitterroot Guitars:

String trees should be shimmed for .075" to .100" string deflection.

More deflection will not keep the string seated, will not increase sustain and WILL cause tuning stability problems.

Arrange springs in a straight line. It doesn't matter if the claw is angled, as long as the springs are running straight and not contacting the body.

Adjust rear edge of bridge to 2/64" at pitch. This is the Fender published specification and it works.

Enjoy Floyd Rose performance from a stock Fender 6-Screw Tremolo.

Adjust rear edge of bridge to 2/64" at pitch. This is the Fender published specification and it works.

Enjoy Floyd Rose performance from a stock Fender 6-Screw Tremolo.

Last edited:

May the specs be with you....