Trigonometry Chilli. Can use measurements and angles to figure things out.@SG John, can you explain trig?

Trigonometry Chilli. Can use measurements and angles to figure things out.@SG John, can you explain trig?

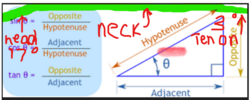

Doc beat me for the reply. Yes, trigonometry. I draw everything on paper first. The neck angle will influence the bridge post location.@SG John, can you explain trig?

Also @SG John, school me if you can ( general gist of things is fine)

Let's say I am at a point where I have a body all shaped and the rout cut in for the neck pocket and pickup routs. Now it is time to fab up the neck from a block of wood. I am venturing to guess we start with a larger depth " stick" in order to fab up the headstock and tenon angles in order to shape the front and back of the neck in between these 2 areas.

Of course, like I said, my guess on how-to would be to figure on cutting the angle on the tenon in order to yield the 3-5* degree angle once inserted in the mortise.

What say you?

Doc beat me for the reply. Yes, trigonometry. I draw everything on paper first. The neck angle will influence the bridge post location.

I won't do a neck mortise until the neck tenon is finished. That way, I can fit the tenon to the mortise while the routing jig is still set up, and the router is at the same depth as my last cut.

The suspense has been killing me for over three years now.

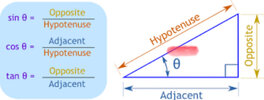

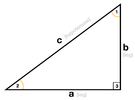

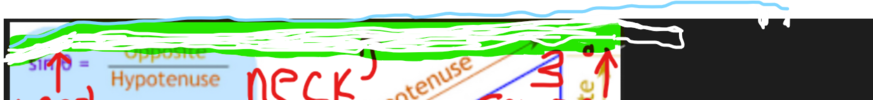

If the hypotenuse (c) of a right triangle is extended, we'll use that as the fingerboard surface. The side opposite (b) will be the location of the bridge posts. But, we'll actually use the side adjacent (a) to calculate where that is.I knew John meant trigonometry, or at least I presumed so. I just could not see how trig can set one's saw or router guide etc to exactly a 3,4,5,etc degree angle on a 3x3x36 block of wood. I guess I am too much of a bits n pieces thinker vs a engineer it, math it, physics it, math it type.

In my mind, in order to get the tenon in a " bent down" position to slide into a flat/horizontal mortise in the guitar body, a neck has to have a down turn in relation to the body in order to get a down turn along the neck's long axis.

I've seen people use a sled that the neck blank is attached to and pushed through a table saw. I use a compound milling vise on my drill press, and set the top part of the angle with a protractor to the top of the vise jaw, then cut it with and endmill shoved in the chuck. Then, when I flip it over and set it on a parallel it comes out even. I would prefere to use a sine plate, but I don't have a good way of using one.Excuse my awful drawing but I added a WHITE neck into a black guitar body and put bridge and tailpiece in white and strings in blue.

SO, if you can think rudimentarily, how do I make the block of wood into that white shape with the 3-5 degree down turn tenon, and 14-17 degree down turn head stock?

Miter saw, band saw, router, etc.

Thank you, John.I've seen people use a sled that the neck blank is attached to and pushed through a table saw. I use a compound milling vise on my drill press, and set the top part of the angle with a protractor to the top of the vise jaw, then cut it with and endmill shoved in the chuck. Then, when I flip it over and set it on a parallel it comes out even. I would prefere to use a sine plate, but I don't have a good way of using one.

View attachment 82897

Can't wait to hear!So anyway my 3+ year ordeal is finally ended. I will post the story in the Ambassador's forum so as to not place my semi-private business out for all to see. Those of you that have been here long enuff to have established ambassadorship are like family to me and I will spill the beans of my trials and tribulations for the past 3.5 years.

Good attitude…adapt and make some noise…good luck sir!So anyway, I have not done any guitar playing for a while now. I started developing a pain in my left index finger only when driving my wife's car and thought it to be the angle/position that I was holding the wheel. The pain has come more frequently now and not just when I drive her car. This has made it very hard to play guitar with no use of my index finger. Several years ago @eSGEe gave me a glass slide. It's packed up now and tucked away in storage, but it gave me the idea to try practice slide. Now that I have some free time in the evening, I might just pull out a guitar and see just how poorly I play.