fitz

Ambassador of DIY

Got a chassis only amp inbound that I'm going to put in the Cabs that currently house my Ceriatone JTM45.

So, I've decided to make new cabs for this amp.

I have this TV armoire that I've been trying to get rid of.

Gave away the side shelves a while ago to a friend, but no one wants the center cabinet because the big TVs don't fit in it.

It's made out of some beautiful solid cherry, so I decided to take it apart and make some furniture style cabs for the Ceriatone.

Getting tired of plywood and tolex...

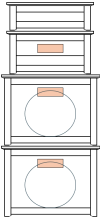

Going to stay with a similar Mission / Craftsman styling and do two 1x12 cabs, headshell and matching shell for the John H M-2.

Lots of large ready-made panels of 3/4" cherry, along with a few slabs of 1".

This would cost a small fortune to buy all this lumber.

Made some scale drawings for final cutting dimensions and a plan for chopping up the panels.

So, I've decided to make new cabs for this amp.

I have this TV armoire that I've been trying to get rid of.

Gave away the side shelves a while ago to a friend, but no one wants the center cabinet because the big TVs don't fit in it.

It's made out of some beautiful solid cherry, so I decided to take it apart and make some furniture style cabs for the Ceriatone.

Getting tired of plywood and tolex...

Going to stay with a similar Mission / Craftsman styling and do two 1x12 cabs, headshell and matching shell for the John H M-2.

Lots of large ready-made panels of 3/4" cherry, along with a few slabs of 1".

This would cost a small fortune to buy all this lumber.

Made some scale drawings for final cutting dimensions and a plan for chopping up the panels.