Which is why I said mostly agree. And I wasn’t just speaking on just amps. My experience has been like yours. Fuse blows. There’s a reason. But not always.Yea, sometimes there is something intermittent that triggers it. Hasn't ever been the case for me yet.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

And then there was one: second amp has failed

- Thread starter Clockworkmike

- Start date

Mechanic one day was joking on how to find a short. Replace the fuse with some wadded up aluminum foil. Stand back and wait for smoke. Found the short.Which is why I said mostly agree. And I wasn’t just speaking on just amps. My experience has been like yours. Fuse blows. There’s a reason. But not always.

Clockworkmike

Ambassador of STACKS in WV SHACKS

Lol if it wasn't such an expensive item to replace, don't think for a second I didn't consider it brieflyMechanic one day was joking on how to find a short. Replace the fuse with some wadded up aluminum foil. Stand back and wait for smoke. Found the short.

Amp Mad Scientist

Ambassador of Heresy

If the fuse is blown we need to do testing of the bias circuit...Appreciate the help fellas!

So this morning, I did the obvious thing first and checked fuses. HT fuse is popped. So, the problem arises here first but the question is, is this common that they just randomly blow or am I looking to something bigger? Unfortunately, a fuse like this (T500mA) isn't something i can get anywhere local, so at a minimum, I gotta order some, in which Ill order some mains fuses as precautionView attachment 99345

You look at the output tubes and see if one looks burned inside (a black spot burned inside the glass)

Now, you probably DO need output tubes...

But don't put the new tubes in yet.

The bias needs to be tested first etc...

or else, the new tubes could burn up.

Don't fry your new tubes.

To test the bias circuit, you test it without the output tubes installed.

If you are ready to do this, let me know and we can give it a go.

marshalltsl

Well-Known Member

As Mad Amp Scientist said I would do some test without power tubes. He help me a lot with my LM6100. He really know what is about.

Jethro Rocker

Ambassador of Live & Loud Action

HT often blows from dead power tube. Have seen that 2 or 3 times. Regardless of bias, try power tubes and see. Only need to try for a few seconds to see if you have sound.

Amp Mad Scientist

Ambassador of Heresy

Anytime the fuse blows: yes there "is" a reason.Which is why I said mostly agree. And I wasn’t just speaking on just amps. My experience has been like yours. Fuse blows. There’s a reason. But not always.

Do not replace the fuse.

Find and correct the real cause first, then replace the fuse.

Wrong speaker impedance.

Wrong setting on amplifier output: 4, 8, 16 ohm is set wrong.

Bad speaker cable: do not use speaker cables made in China. (defective 1/4" plugs !)

Marshall Plexi: defective speaker selector.

These plugs go bad all the time. These plugs cause intermittent connections, which will blow the fuse or fry the output transformer.

These plugs go bad all the time. These plugs cause intermittent connections, which will blow the fuse or fry the output transformer.

Do not use this, replace it with a reliable selector switch.

Bias is set wrong.

Screen Grid Resistors are missing from circuit. ( year 1968 plexi)

Bad output tubes

Guys..... I not disagreeing with your assessments. 99% of the time when a fuse blows or a breaker trips, there is a reason. Totally agree with you. All I'm suggesting is...... the fuse is the weak link in the system. There's a reason for that...... a lot of electricity flows through them every time the unit is turned on. Whether that's an amp.... your car.. whatever. A fuse, like a light bulb, is a wear item. They do get tired and they do fail for no apparent reason. Which is why most people think to replace the fuse first as diagnostics. Many times in my line of work (tractor shops and marina as a mechanic and parts department) and personal experience.... the fuse has been replaced fully expecting it to blow and not only did it fix the issue.... it did not blow again.Anytime the fuse blows: yes there "is" a reason.

Do not replace the fuse.

Find and correct the real cause first, then replace the fuse.

Last edited:

Clockworkmike

Ambassador of STACKS in WV SHACKS

Won't be able to get to it today, but most likely tomorrow I can! ( wife's birthday today so I'm tied up a bit with things). I have a bias tester that plugs into my DMM, which I used before. I will definitely get back with you on this and thank you for the help!If the fuse is blown we need to do testing of the bias circuit...

You look at the output tubes and see if one looks burned inside (a black spot burned inside the glass)

Now, you probably DO need output tubes...

But don't put the new tubes in yet.

The bias needs to be tested first etc...

or else, the new tubes could burn up.

Don't fry your new tubes.

To test the bias circuit, you test it without the output tubes installed.

If you are ready to do this, let me know and we can give it a go.

Amp Mad Scientist

Ambassador of Heresy

You won't use a bias probe to test this.Won't be able to get to it today, but most likely tomorrow I can! ( wife's birthday today so I'm tied up a bit with things). I have a bias tester that plugs into my DMM, which I used before. I will definitely get back with you on this and thank you for the help!

Take out the power tubes.

Set meter for DC volts.

Attach the black probe to the chassis.

Attach the red probe to pin 5 of the output tube socket.

(there are pin numbers stamped on the socket)

Turn the power on but leave standby in warm-up position

Do not turn the standby to operate position.

There should be negative DC voltage on pin 5 of the output tube socket.

Now, turn the bias control all the way to the left and write the voltage down.

Turn the bias control slowly, to the right.

Does the voltage adjust up / down smoothly?

or is there any dead spots in the adjustment range? Any erratic spots in the adjustment range of the pot?

Make sure it adjusts up / down with no bad spots in the adjustment range as you turn the pot all the way left and right.

Note:

If there "is" bad spots in the adjustment range, stop here.

Do not install the tubes or play the amp until the bias pot is replaced.

A bad bias pot is major trouble, don't risk using it, replace it with a new one.

"If" the bias pot is OK:

turn it all the way to the right, and write the DC voltage reading down.

Now what was your far left voltage reading? (report)

What was your far right voltage reading? (report)

Now repeat this for all the output tube sockets and report the DC voltage readings.

We are making sure that all the output tube sockets are getting proper voltage to pin 5. (very important)

Leak down test:

Set the voltage on pin 5 to -42 volts, DC.

"were" you able to adjust the bias pin 5 voltage to -42 volts DC?

If not, STOP HERE. The bias circuit needs more testing and replacement parts.

If yes, proceed.

Now attach your red probe to pin 5 again, turn the standby to "operate."

How much did the pin 5 DC voltage change, when you turned the standby to "operate?" (make a note of this voltage)

Now turn the standby to warm-up position again.

Now repeat this test for all the output tube sockets one at a time. Note how much the pin 5 voltage changed, for each socket, when you turned the standby to "operate."

Now report your readings for each socket.

This test: checks to see if the coupling capacitors between the phase inverter and the power tubes pin 5 are working properly.

If the voltage stays the same on pin 5, when you turn the standby to operate, that's good !

If the pin 5 voltage changes a whole bunch when you turn the standby to operate, that's very bad.

It means that the coupling capacitor is shorting out, and B+ is leaking into the bias circuit !

OR, it means that your circuit board insulation is failing (just as the DSL board insulation fails...)

In any case, test all the output sockets and write your results down, and report the results.

If there is any defect detected, do not put the tubes in.

Because your new tubes can be destroyed.

FIRST: test and verify proper bias operation.

NEXT: fix any problem that was detected.

LAST: after everything is verified, then put the tubes in, and bias the amp as usual.

DO NOT "just put the tubes in, and see what happens."

Do not acquire the habits, of hacks.

Don't risk damaging anything, leave tubes out, until you verify the bias operation FIRST.

Last edited:

Clockworkmike

Ambassador of STACKS in WV SHACKS

Alright, so I got around to this and here are my results following your instructions, in which I did not deviateYou won't use a bias probe to test this.

Take out the power tubes.

Set meter for DC volts.

Attach the black probe to the chassis.

Attach the red probe to pin 5 of the output tube socket.

(there are pin numbers stamped on the socket)

Turn the power on but leave standby in warm-up position

Do not turn the standby to operate position.

There should be negative DC voltage on pin 5 of the output tube socket.

Now, turn the bias control all the way to the left and write the voltage down.

Turn the bias control slowly, to the right.

Does the voltage adjust up / down smoothly?

or is there any dead spots in the adjustment range? Any erratic spots in the adjustment range of the pot?

Make sure it adjusts up / down with no bad spots in the adjustment range as you turn the pot all the way left and right.

Note:

If there "is" bad spots in the adjustment range, stop here.

Do not install the tubes or play the amp until the bias pot is replaced.

A bad bias pot is major trouble, don't risk using it, replace it with a new one.

"If" the bias pot is OK:

turn it all the way to the right, and write the DC voltage reading down.

Now what was your far left voltage reading? (report)

What was your far right voltage reading? (report)

Now repeat this for all the output tube sockets and report the DC voltage readings.

We are making sure that all the output tube sockets are getting proper voltage to pin 5. (very important)

Leak down test:

Set the voltage on pin 5 to -42 volts, DC.

"were" you able to adjust the bias pin 5 voltage to -42 volts DC?

If not, STOP HERE. The bias circuit needs more testing and replacement parts.

If yes, proceed.

Now attach your red probe to pin 5 again, turn the standby to "operate."

How much did the pin 5 DC voltage change, when you turned the standby to "operate?" (make a note of this voltage)

Now turn the standby to warm-up position again.

Now repeat this test for all the output tube sockets one at a time. Note how much the pin 5 voltage changed, for each socket, when you turned the standby to "operate."

Now report your readings for each socket.

This test: checks to see if the coupling capacitors between the phase inverter and the power tubes pin 5 are working properly.

If the voltage stays the same on pin 5, when you turn the standby to operate, that's good !

If the pin 5 voltage changes a whole bunch when you turn the standby to operate, that's very bad.

It means that the coupling capacitor is shorting out, and B+ is leaking into the bias circuit !

OR, it means that your circuit board insulation is failing (just as the DSL board insulation fails...)

In any case, test all the output sockets and write your results down, and report the results.

If there is any defect detected, do not put the tubes in.

Because your new tubes can be destroyed.

FIRST: test and verify proper bias operation.

NEXT: fix any problem that was detected.

LAST: after everything is verified, then put the tubes in, and bias the amp as usual.

DO NOT "just put the tubes in, and see what happens."

Do not acquire the habits, of hacks.

Don't risk damaging anything, leave tubes out, until you verify the bias operation FIRST.

I removed the power tubes and took my meter, grounded the black lead to the chassis and the red lead to Octal socket #5 of V6 ( the power tube on the left). I was reading about -28.3VDC. I turned the LEFT bias adjustment down to the left and it didn't change anything. When I turned the RIGHT bias adjustment down to the left, it dropped to -25.5VDC. When I turned it all the way to the right, slowly, it climbed steadily until it maxed out at -33.2VDC

I did this same thing for V7 ( the power tube on the right) reading -28.3VDC. Once again, the RIGHT bias adjustment did nothing, but when i turned the LEFT bias adjustment, it began to change. I turned it all the way to the left, it dropped to -25.5VDC, slowly turning it to the right, it steadily climbed to -33.2VDC.

At no point am I reading anything higher than -33.3VDC, which in your step procedure you mentioned that i should get it to -42VDC. After adjusting to a maximum range, I turned the standby to operate and notice no change: it remained at -33.2VDC.

I know Marshall says this should be biased to anywhere between -36VDC to a maximum of -45VDC, where as a typical EL34 should have a bias voltage of -38VDC. But Im nowhere near even it's lowest recommended setting, so something is wrong, right? Not to mention, everything I've read or seen on biasing these shows the left bias adjustment for the left side tubes and the right bias adjustment for the right side tubes, yet mine is operating on opposing sides

Clockworkmike

Ambassador of STACKS in WV SHACKS

I know the dreaded Bias Drift wasn't SUPPOSED to affect the DSL50, but could this be what I'm dealing with?

Amp Mad Scientist

Ambassador of Heresy

You should be able to get - 45 VDC.Alright, so I got around to this and here are my results following your instructions, in which I did not deviate

I removed the power tubes and took my meter, grounded the black lead to the chassis and the red lead to Octal socket #5 of V6 ( the power tube on the left). I was reading about -28.3VDC. I turned the LEFT bias adjustment down to the left and it didn't change anything. When I turned the RIGHT bias adjustment down to the left, it dropped to -25.5VDC. When I turned it all the way to the right, slowly, it climbed steadily until it maxed out at -33.2VDC

I did this same thing for V7 ( the power tube on the right) reading -28.3VDC. Once again, the RIGHT bias adjustment did nothing, but when i turned the LEFT bias adjustment, it began to change. I turned it all the way to the left, it dropped to -25.5VDC, slowly turning it to the right, it steadily climbed to -33.2VDC.

At no point am I reading anything higher than -33.3VDC, which in your step procedure you mentioned that i should get it to -42VDC. After adjusting to a maximum range, I turned the standby to operate and notice no change: it remained at -33.2VDC.

I know Marshall says this should be biased to anywhere between -36VDC to a maximum of -45VDC, where as a typical EL34 should have a bias voltage of -38VDC. But Im nowhere near even it's lowest recommended setting, so something is wrong, right? Not to mention, everything I've read or seen on biasing these shows the left bias adjustment for the left side tubes and the right bias adjustment for the right side tubes, yet mine is operating on opposing sides

There is some stuff wrong so don't play the amp.

Do you have enough soldering skills to change parts on a PC board?

If not, send it to Sysco, he'll fix anything

but seriously you probably have to remove replace parts and the circuit board is very delicate.

Do you know anybody who can solder PC boards?

You can send it here, but it's a long way from West By God, and you need to pack it really good.

Last edited:

Clockworkmike

Ambassador of STACKS in WV SHACKS

It would be awesome if I had a qualified person like you, Sysco or a few others nearby, but as it stands there's only 2 within 2hrs of me and neither are responding to phone calls. So, that narrows down my options. Marshall isn't any help as I've contacted them to give me some names but still waiting.You should be able to get - 45 VDC.

There is some stuff wrong so don't play the amp.

Do you have enough soldering skills to change parts on a PC board?

If not, send it to Sysco, he'll fix anything

but seriously you probably have to remove replace parts and the circuit board is very delicate.

Do you know anybody who can solder PC boards?

You can send it here, but it's a long way from West By God, and you need to pack it really good.

So, I could attempt this myself if I have no options left. Im comfortable enough with a soldering tool on electronics, as in not damaging delicate components and making a clean connection. But I feel like I'm way out of my league troubleshooting these things: there's no way I could ever figure any of this out myself.

Amp Mad Scientist

Ambassador of Heresy

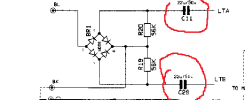

C11, C29, 22uF 50V BIPOLAR Capacitors Those two caps need to be replaced.

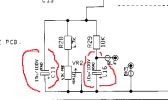

C11, C29, 22uF 50V BIPOLAR Capacitors Those two caps need to be replaced. These two 10uF 100V electrolytic caps need to be replaced.

These two 10uF 100V electrolytic caps need to be replaced.Note:

There is probably two different "C11" caps in the amplifier, one is BIPOLAR the bias rectifier, the other is regular electrolytic filter cap at the bias control.

Watch out with these amps, because there is duplicate cap numbers on the schematic and on the boards. Be sure not to confuse them.

Last edited:

Amp Mad Scientist

Ambassador of Heresy

OK well there's 4 caps you can replace if you are feeling ducky.It would be awesome if I had a qualified person like you, Sysco or a few others nearby, but as it stands there's only 2 within 2hrs of me and neither are responding to phone calls. So, that narrows down my options. Marshall isn't any help as I've contacted them to give me some names but still waiting.

So, I could attempt this myself if I have no options left. Im comfortable enough with a soldering tool on electronics, as in not damaging delicate components and making a clean connection. But I feel like I'm way out of my league troubleshooting these things: there's no way I could ever figure any of this out myself.

Clockworkmike

Ambassador of STACKS in WV SHACKS

I certainly appreciate your knowledge and time my friend. Im ordering them now and will conduct this!OK well there's 4 caps you can replace if you are feeling ducky.

Clockworkmike

Ambassador of STACKS in WV SHACKS

One quick question my friend: is this for the SLX or the DSL50 or is it the same caps either way?View attachment 99399 C11, C29, 22uF 50V BIPOLAR Capacitors Those two caps need to be replaced.

View attachment 99401 These two 10uF 100V electrolytic caps need to be replaced.

Note:

There is probably two different "C11" caps in the amplifier, one is BIPOLAR the bias rectifier, the other is regular electrolytic filter cap at the bias control.

Watch out with these amps, because there is duplicate cap numbers on the schematic and on the boards. Be sure not to confuse them.

Amp Mad Scientist

Ambassador of Heresy

OK no worries.I certainly appreciate your knowledge and time my friend. Im ordering them now and will conduct this!

Don't forget the 22 uF caps are bipolar, not regular filter caps.

Regular filter caps have (+) (-)

Bipolar caps have no polarity.

Amp Mad Scientist

Ambassador of Heresy

I see these 4 caps on the SLX schematic.One quick question my friend: is this for the SLX or the DSL50 or is it the same caps either way?

But DSL uses the same bipolar caps 22uF 50V.