Ghostman

Ambassador of the SuperNatural

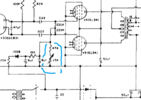

Hello Gents. A buddy of mine has an Origin 50 that he inadvertently left on for a few days. When he came back to it, he turned it off, let it cool down and then when he turned it back on, a power tube blew. Took out the tube and the fuse. He replaced both, but now he can't bias the amp. It's stuck on 91ma and the bias pot does nothing.

Anyone have any notions of where I should suggest he look? He's fairly electronic capable, handy with soldering etc.

Anyone have any notions of where I should suggest he look? He's fairly electronic capable, handy with soldering etc.