ivan H

Ambassador of Tubes & Grooves

Looking into it, the Vishay Sprague Atom capacitors were at first manufactured in Indonesia, but Vishay later moved the manufacture of all "leaded" components to China (where the greatest bulk of Vishay components are manufactured). Vishay also own Cornell Dublier & all Cornell Dublier components, including the CD electrolytics are manufactured in China. Vishay own numerous manufacturing plants (passives, semiconductors etc etc), all over mainland China & Hong Kong. Vishay is an American corporation (global headquarters Malvern PA), not Canadian.Sprague was purchased by Vishay Canada.

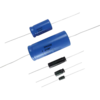

But they still make a lot of old style caps.

As you can see, the outside foil is clearly marked on every decoupling capacitor.

ARS

Not used in any Marshall Laney Hiwatt as far as I have seen. Unless somebody installed them.

Really cheap capacitors from China. No specification sheet. Like, the cheapest parts from China ever made.

Sold by an electronics supply "ARS" in California.

I bought some and tried them, they suck. Worse than "Illinois Capacitor," which is made in China too.

We used to buy a lot of parts from ARS in the 70s-80s. They used to sell tubes and other parts.

ARS Electronics Since 1947 - Home Page - Electron Tubes - Amp Tubes - RF Heating Tubes - Broadcast Transmitter Tubes

ARS Electronics Wholesale Electron Tube Distributor Since 1947, replacement new transmitter tubes and rebuilt transmitter tubes , replacement industrial microwave and magnetron tubes, tubes for radio frequency (rf) heating including rf plastic heating, rf vinyl sealing, rf welder also audio...www.arselectronics.com

The ARS capacitors were stock equipment in the Marshall SPL JH (Jimi Hendrix) & also I believe the HW (hardwired) series amps, to name a couple.

Watford Valves in the UK are a supplier of ARS capacitors (& Vishay Sprague Atom). Their site list Marshall, Laney & Hiwatt as using these ARS capacitors in (some of) their amps. Further, they claim the ARS capacitors were made to replicate the UK made LCR capacitors that UK amp manufactures had used (before LCR went out of production), but with better specifications & a longer service life of 3,000 hours.

Given that Marshall's designers & tech staff had the opportunity to use any electrolytic filter capacitors available when producing their "top of the line" JH & HW models, the fact that they specified the ARS capacitors be used would seem to indicate they thought them the most suitable.

Now I may be wrong, but I'm guessing those Marshall staffers have just a little more combined knowledge, experience & know-how than you do when it comes to ascertaining whether a component is a quality choice for a this application, or whether it "sucks".

Illinois Capacitor were OEM for Peavey amps. They don't seem to have any problems with premature filter cap failure or any other problem pertaining to them. Cheers

Last edited: