I think at least 1X GFI 20A circuits in the garage, 2X 20A GFI required in the kitchen, and 1X 20A outdoor GFI too.

I thought that was minimum.

If he wants 14 GA wire, you need to talk it over w/ him; fireside chat.

We have title 24 here in Left Coast, which makes stuff like LEDs mandatory, and bathroom humidity sensors, and all other robotic light switches sort of stuff.

Yeah pretty much the entire garage is considered a GFCI area and typically you'd have a minimum of at least one circuit.

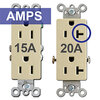

As for #14 AWG, its fine as long as you use 15A Breakers and 15A Receptacles accordingly. At the current prices of breakers and outlets, there's almost no difference in the cost between 15 and 20. Wire cost between 14 and 12 gauge is certainly a big difference though and something to consider in budgeting.

That California Title 24 is pretty astringent! I get it though, as its energy focused and Green Certified. California often leads the industry standards in electrical requirements, especially influencing the NEC every 3 years

Pardon the formality but heres the requirements on GFCIs in general.

210.8(A) Dwelling Units. All 125-volt, single-phase, 15- and 20- ampere receptacles installed in the locations specified in 210.8(A)(1) through (10) shall have ground-fault circuit interrupter protection for personnel.

(1) Bathrooms

(2) Garages, and also accessory buildings that have a floor located at or below grade level not intended as habitable rooms and limited to storage areas, work areas, and areas of similar use

(3) Outdoors

Exception to (3): Receptacles that are not readily accessible and are supplied by a branch circuit dedicated to electric snow-melting, deicing, or pipeline and vessel heating equipment shall be permitted to be installed in accordance with 426.28 or 427.22, is applicable.

(4) Crawl spaces — at or below grade level

(5) Unfinished portions or areas of the basement not intended as habitable rooms

Exception to (5): A receptacle supplying only a permanently installed fire alarm or burglar alarm system shall not be required to have ground-fault circuit-interrupter protection.

Informational Note: See 760.41(B) and 760.121(B) for power supply requirements for fire alarm systems.

Receptacles installed under the exception to 210.8(A)(5) shall not be considered as meeting the requirements of 210.52(G).

(6) Kitchens — where the receptacles are installed to serve the countertop surfaces

(7) Sinks — where receptacles are installed within 1.8 m (6 ft) from the top inside edge of the bowl of the sink

(8) Boathouses

(9) Bathtubs or shower stalls — where receptacles are installed within 1.8 m (6 ft) of the outside edge of the bathtub or shower stall

(10) Laundry areas

we don't install any 15A circuits.

we don't install any 15A circuits.