fitz

Ambassador of DIY

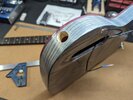

Here's the build pics so far on my almost done tele build.

Posted already in the British amp forum I also frequent, so thought I'd share here too.

Kinda started when I traded a pedal for this no-name custom tele neck.

Had this ash slab from an abandoned idea, and picked up this purpleheart board from the local Rockler store.

Like I said, it's almost done.

I was figuring a fairly high chance of potential catastrophic failure on this, so I didn't post any pics until I actually had a functional guitar.

Here's how it looked the other night before I took it all apart again for a final coat of clear.

The back of the body and neck are stained with "Phantom Gray", front of the headstock is stained black (awaiting a custom decal), and the purpleheart cap is nothing but clear lacquer.

Pups are GF'Trons Alnico V 6.6k / 6.0k set from Guitar Fetish, as is most of the hardware.

(Its' a clear pickguard with a black beveled edge, if you're wondering...)

Posted already in the British amp forum I also frequent, so thought I'd share here too.

Kinda started when I traded a pedal for this no-name custom tele neck.

Had this ash slab from an abandoned idea, and picked up this purpleheart board from the local Rockler store.

Like I said, it's almost done.

I was figuring a fairly high chance of potential catastrophic failure on this, so I didn't post any pics until I actually had a functional guitar.

Here's how it looked the other night before I took it all apart again for a final coat of clear.

The back of the body and neck are stained with "Phantom Gray", front of the headstock is stained black (awaiting a custom decal), and the purpleheart cap is nothing but clear lacquer.

Pups are GF'Trons Alnico V 6.6k / 6.0k set from Guitar Fetish, as is most of the hardware.

(Its' a clear pickguard with a black beveled edge, if you're wondering...)