chilipeppermaniac

Ambassador of Decibels

Funny thing is I still don't know what a Master Volume is. I mean precisely. I know what one is, kind of. LOL

Ebidis, you are relatively new here and to me, but I had almost 0 electronics experience before joining here and another forum.

I had need of some fixes to my '72 Marshall 50 watt JMP amp. I would blow fuses and or lose sound while playing. Totally dead sound despite amp still working. I wound up going to a local tech who had a good reputation. I got new tubes, new caps, and he called it good to go.

I basically took it as he knew what he was doing and with it playing, I took it home and eventually went to play it again. Sadly after a short period, it failed again. This time, he hooked up a tester in front of me and told me the OT was done. I told him I would buy the new Marstran one and have him install it. Save me the old one. Well, by the time I went to pick it up, I had totally loaded it up and got 5 minutes down the road and remembered I had forgotten to get the OEM tranny back. Called him, and he told me he does not save those things. At this, I lost all faith in his work and his honesty as on my first trip there, he had shown me his shop and boxes of parts I knew were not new parts. To quote Bryan Wallace at Marstran, the OEM trans was worth more dead, than His new one was brand new. Anyhow, even with the new one, my amp was still cutting out.

Upon explaining this on here, another member really encouraged me and prodded me with his statement of faith, that he believed in me and that I could fix it.

This began my postings for help from electronics experienced members as well as acquiring books, googling, and you tube videos. In short time, Ivan H, Sysco, DonP, Bastarddon, 67 plexi and some fellas from Marshall amps forum taught me a lot as we basically went over the amp to get a few wires returned to proper places, checked voltages on Trans, cap values, resistors etc. The amp should have been in full working order when I was finished. It would fire up and make sound every time I completed a repair and check, until the day I really thought I would give it a good go. Strummed a few chords and all of a sudden, the sound fizzed out to NADDA.

I was almost at a give up point then gave it one more shot and tried the chopstick test. As I learned online, one can safely test for flaws using a non conducive probe like a wooden chop stick. I sure got lucky and actually did get the amp to make sound and lose sound when I finally touched the probe to the pins/wires on the back of the OHMs selector switch. The final diagnosis was that the attached Ohms socket and the removable 2 pronged cap with the little window in it was losing good contact between the female ferrules and the male prongs. This caused the no load condition to be present, if that is how I understand what results when loss of a signal occurs at this selector.

Some experts stress that this selector should be replaced in order to prevent wiping out a tranny,. however I disassembled mine and gently squeezed the female tubes tighter on all the connections on both the Ohms selector and the Volts selector switches. This restored the operations of both to good snug fits, no loss of contact and for my use, I will not be plugging and unplugging the selectors 1000 times a year for speaker cab changes or anything to wear it out loose again. I set the pronged cap to my only needed setting, 16 ohm and forget about it.

Ebidis, Now that was my long winded story. But for those members I mentioned who helped me along the way, the knowledge you guys shared, has equipped me with the skills to repair additional amps. My fixes will be to remedy things like mouse chewed wires, a chewed coupling cap, to replace filter capacitors, and to undo a hard wired ohms selector switch to make it adjustable like the repaired one I mentioned above.

I know it likely sounds like riding a bike to you experienced Electronics guys, but every time I learn about Phase Inverters, Slope resistors, Diode vs Bridge rectifiers, tone stacks, Ohm's law, Resistor band calculations, etc, the more excited I get to put these all to use.

Thanks to all for adding to my learning of this invaluable treasure of knowledge.

It's this little knob. It should always be around 8 or 9...at least that's about as much as I know about it...

View attachment 62162

Oh MAN, Robert, If I ever put my Master volumes, or even my Channel 1, Channel 2 volumes up to 8 on my amps, the walls would shake and car windows would explode.

Just turn whatever you got all the way up .

Both my ancient Traynor and Fender only have a Master Volume. No Gain Knob like a lot of new amps have.Funny thing is I still don't know what a Master Volume is. I mean precisely. I know what one is, kind of. LOL

From the other thread you posted, I know why.P.S. my Origin 50 is both louder and clearer than the studio's JCM800...

You can either hard wire the 16 ohm tap to the jack permanently.....(safest solution)

or

buy a selector switch and make an adapter plate to mount it so the chassis hole doesn't need to be modified or drilled.

Unfortunately even when you bend the contacts back, the original selector will eventually fail again...

due to oxide forming on the contacts, or loose contacts.

The original selector was pretty unreliable, the weakest link in the amp.

And it will definitely fry the OT or tubes / sockets...and should be replaced IMHO.

But too bad because there are so few techs who pay attention to speaker problems...speaker wiring rarely gets tested properly.

And, the old transformer may have still been good for all you know.

When I fix an amp (like yours problem) I always flex test the entire speaker chain and test the cabinet.

There are so few people who understand WHY I am concerned about the speaker load.

Thanks AMS,,,,,,,,,,,,,,,,,,,,, All you have mentioned except your last 2 sentences is exactly as I have discovered through my research.

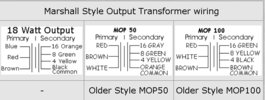

When I first fixed my Ohms selector on my 50 watt JMP, I purchased some New Style Ohms selectors. I saw how to make an adapter to fit it into the chassis for " upgrading the old style selectors.

On my orange Tolexed, '78 Superlead/bass head the guy I got it from either lost the window cap or just BS told me he had. This left me to research the status of that selector. It is Hard wired. Here is a Pic of that area. Can you confirm what OHMs the amp is hard wired set to? I am seeing it as 16 ohm as the green jumper wire goes from the center to the 16 ohm pin on the selector.

View attachment 62177

And like you said, I am sure the tech did not test any speaker to the amp once done the Trans replacement, and as I saw, with the intermittent issue and my lack of electronics knowledge, I could not illiterate any specific component tests I would have known to do. That is why I went to a tech in the first place. I sure wish I would have known Jeff Bober back then. I trust him way more that the guy I had. At least now I am balancing out that expensive lesson for some cheaper ones now that I am more learned and skilled.

I would be interested in an explanation of what you mean by "Flex Test"the entire speaker chain and test the cabinet. I already know about checking a single speaker or 2x12, 4x12 cab, But do you mean like confirming the OHMs of a combination of speakers when daisy chained? Is that what you mean " Flex Test the entire speaker chain?"

Thanks

I was almost at a give up point then gave it one more shot and tried the chopstick test. As I learned online, one can safely test for flaws using a non conducive probe like a wooden chop stick. I sure got lucky and actually did get the amp to make sound and lose sound when I finally touched the probe to the pins/wires on the back of the OHMs selector switch. The final diagnosis was that the attached Ohms socket and the removable 2 pronged cap with the little window in it was losing good contact between the female ferrules and the male prongs. This caused the no load condition to be present, if that is how I understand what results when loss of a signal occurs at this selector.

Some experts stress that this selector should be replaced in order to prevent wiping out a tranny,. however I disassembled mine and gently squeezed the female tubes tighter on all the connections on both the Ohms selector and the Volts selector switches. This restored the operations of both to good snug fits, no loss of contact and for my use, I will not be plugging and unplugging the selectors 1000 times a year for speaker cab changes or anything to wear it out loose again. I set the pronged cap to my only needed setting, 16 ohm and forget about it.

P.S. my Origin 50 is both louder and clearer than the studio's JCM800...

Duct tape fixes anything.I've had this piece of duct tape on my 100 watt JMP for the past twenty odd years. Does the job, because it's always been set to 16 Ohms.

View attachment 62188

My 100 watt JMP is a very loud and clear amp, even with a master volume. Many people have commented on how great this amp sounds. This photo has it in it's old box, held together with large pieces of steel angle. It looks like it was thrown off of a truck, but sure does sound good.

View attachment 62189

Excellent job on cleaning off all that puke and toasty wire ends. Why did you replace the crusty carbon comps?I started fixing that amp, but it's a career for sure.

Big commitment.

View attachment 62137

View attachment 62138

View attachment 62139

View attachment 62140