I wrote previously about my difficulties with my YelloStrat tuning issues, specifically that it went sharp after every tremolo bend.

The Warmoth neck came equipped with a Graph Tech Tusq XL nut that was CNC machined. The slots measured .047, .037, .027, .017 .012 & .010 - exactly .001" wider than the strings and cut parallel to the fretboard.

Here's the neck as delivered:

As one might expect, I had tuning issues. Most articles say the nut slot should be no more than. 002" wider than the string. Ok, I had that. Other articles said to.polish the other and I did that too, but it still went sharp on dives...even shallow ones.

Another issue with the short, vintage tuners was the angle on the low 'E' was quite extreme. This is due to the relatively short post on the hollow shaft tuners:

I cut each slot downward towards the tuning keys. The notch in the neck is not from filing. It is from me pushing down on the string behind the nut.

No matter what I tried, the low 'E' would go sharp by 4 or 5 cents everything I would release the bar. Fretting and bending a note would return to pitch.

My local tech - 30 years with Fender - agreed to setup YelloStrat but wanted $200.00 to do it. He also told me,, " The Gotoh (SD-91) tuners are cheap, Jap junk. You need to get them off of there."

That statement really turned me off. I think $200.00 is certainly fair and about the going rate here in SoCal for a full setup, but then, i decided against it, because I could buy a brand new, yellow cream Fender hardtail body from a mutual friend for $100.00, and a Gotoh hardtail bridge for $40.00 and solve the problem permanently.

Tonight, I decided to conduct a few experiments. I attached a dial indicator to my headstock and checked each tuning post for movement.

When I press my tremolo bar down to the pickguard, I can drop 11 semitones to D#. If I pull up, I can raise my 'g' string to b flat. This works out to the Fender spec of the bridge plate being 3/32" off the body.

Not one tuner showed any movement, forward or backwards.

Then, I started examing the strings as they moved through the nut under magnification. Sure enough, the low 'E' was hanging up.

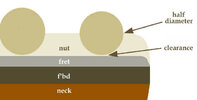

I took the low 'E' slot out to .049" and the string still hung up in the nut. Then I remembered an article about nuts written by Paul Hostetter. Paul said the nut slot needs to be "funnel shaped" in order to guide the string, but not bind it, with only about the front most 2/3 of the nut contacting the string.

Paul posted these diagrams to illustratehis point:

I started by opening the low 'E' slot with a .052" round file. I then angled the slot down towards the tuning keys. The idea was to alleviate as much string pressure as possible on the nut.

Next, I opened each slot to form a "double bell" shape. The low 'E' has the largest bell and each successive string has a smaller bell shape.

I retained my setting of .020" at the first fret:

Guess what??? Zero tuning issues after 15 all-the-way- to-the-pickguard dive bombs.

Interesting!!!!!

The Warmoth neck came equipped with a Graph Tech Tusq XL nut that was CNC machined. The slots measured .047, .037, .027, .017 .012 & .010 - exactly .001" wider than the strings and cut parallel to the fretboard.

Here's the neck as delivered:

As one might expect, I had tuning issues. Most articles say the nut slot should be no more than. 002" wider than the string. Ok, I had that. Other articles said to.polish the other and I did that too, but it still went sharp on dives...even shallow ones.

Another issue with the short, vintage tuners was the angle on the low 'E' was quite extreme. This is due to the relatively short post on the hollow shaft tuners:

I cut each slot downward towards the tuning keys. The notch in the neck is not from filing. It is from me pushing down on the string behind the nut.

No matter what I tried, the low 'E' would go sharp by 4 or 5 cents everything I would release the bar. Fretting and bending a note would return to pitch.

My local tech - 30 years with Fender - agreed to setup YelloStrat but wanted $200.00 to do it. He also told me,, " The Gotoh (SD-91) tuners are cheap, Jap junk. You need to get them off of there."

That statement really turned me off. I think $200.00 is certainly fair and about the going rate here in SoCal for a full setup, but then, i decided against it, because I could buy a brand new, yellow cream Fender hardtail body from a mutual friend for $100.00, and a Gotoh hardtail bridge for $40.00 and solve the problem permanently.

Tonight, I decided to conduct a few experiments. I attached a dial indicator to my headstock and checked each tuning post for movement.

When I press my tremolo bar down to the pickguard, I can drop 11 semitones to D#. If I pull up, I can raise my 'g' string to b flat. This works out to the Fender spec of the bridge plate being 3/32" off the body.

Not one tuner showed any movement, forward or backwards.

Then, I started examing the strings as they moved through the nut under magnification. Sure enough, the low 'E' was hanging up.

I took the low 'E' slot out to .049" and the string still hung up in the nut. Then I remembered an article about nuts written by Paul Hostetter. Paul said the nut slot needs to be "funnel shaped" in order to guide the string, but not bind it, with only about the front most 2/3 of the nut contacting the string.

Paul posted these diagrams to illustratehis point:

I started by opening the low 'E' slot with a .052" round file. I then angled the slot down towards the tuning keys. The idea was to alleviate as much string pressure as possible on the nut.

Next, I opened each slot to form a "double bell" shape. The low 'E' has the largest bell and each successive string has a smaller bell shape.

I retained my setting of .020" at the first fret:

Guess what??? Zero tuning issues after 15 all-the-way- to-the-pickguard dive bombs.

Interesting!!!!!